OUR SERVICES

SERVICES OVERVIEW

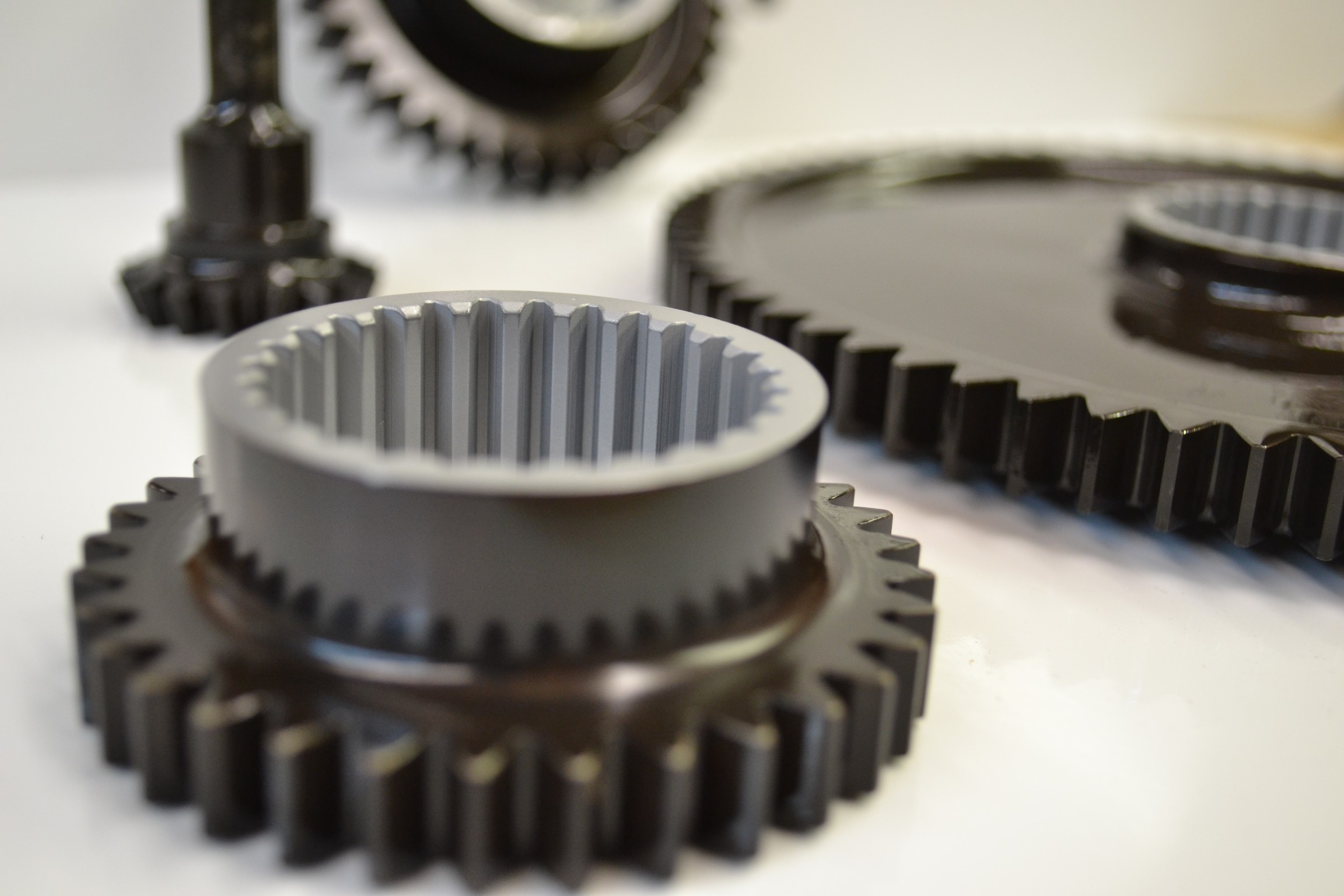

Offers increased life and superior resistance to wear, friction and corrosion because of its excellent lubricity properties.

This process will debur and polish parts to produce a bright finish as well as passivate your parts. The electrolytic process for the removal of contaminants in the base material.

Provides enhanced corrosion protection and aesthetic appeal. It is a chemical process used as a rust inhibitor for the underlaying metal.

A high corrosion resistance process designed to produce semi-bright deposits for engineering applications where uniformity of coating is important.

The chemical treatment of a stainless steel surface with a mild acid. This is typically done to remove any foreign material from the surface of the metal which enhances the corrosion resistance of the stainless steel surface.

Is best suited for engineering purposes for solderable surfaces, electrical contact characteristics, high electrical and thermal conductivity, thermocompression bonding, and other applications. Good corrosion resistance, good solderability.

Is a great way to remove surface contaminants and rust from parts before plating and ensures proper cleaning and preparation. It also gives the metal a fine texture that allows the plating to adhere the base metal.

Is applied to a base metal to provide excellenct resistance to corrosion in most marine and alkaline enviroments. Cadmium also acts as a sacrificial protection to the underlaying metal by being preferentially corroded when damaged.